| Matahari Jaya Hard Chrome

Professional in hard chroming and repairing |  |

|---|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ||

| Technical Data | |

| Plating on basic material : Steel, Casting, Stainless Steel, non–Ferrous metal. | |

Hardness up to approx. 1100 HV 0.3/2 Low friction ( Coefficient of friction with sliding friction between 0.06 and 0.16, dependent on material pairs ). | |

High reflectivity up to approx. 90 %. | |

Linear coefficient of thermal expansion 6,6 - 8,5 10-6 K-1. | |

Melting point 1800 - 1900°C. | |

Thermal conductivity at 20°C = 69 W/(m.K.). | |

Density = 6,9 - 7,2 g/dm3. | |

| Modulus of elasticity 135 000 - 160 000 N/mm2 | |

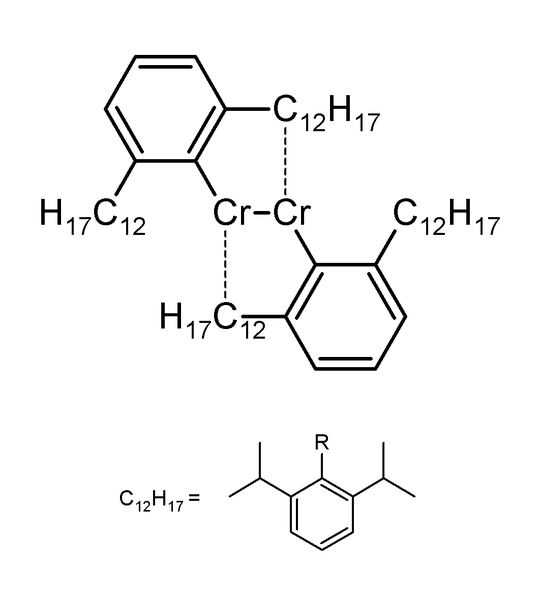

| High purity (99.999 % = 5N) chromium crystals, produced by chemical transport reaction through decomposition of chromium iodides, as well as a high purity (99,95 % = 3N5) 1 cm3 chromium cube for comparison. Chromium metal left standing in air is passivated by oxygen, forming a thin protective oxide surface layer. This layer is a spinel structure only a few atoms thick. It is very dense, and prevents the diffusion of oxygen into the underlying material. This barrier is in contrast to iron or plain carbon steels, where the oxygen migrates into the underlying material and causes rusting. The passivation can be enhanced by short contact with oxidizing acids like nitric acid. Passivated chromium is stable against acids. The opposite effect can be achieved by treatment with a strong reducing agent that destroys the protective oxide layer on the metal. Chromium metal treated in this way readily dissolves in weak acids. | ||

|

|---|

|

|